Intro to PCE Powder: The Third Generation of Superplasticizers Reshaping Modern Concrete

Polycarboxylate ether (PCE) powder has actually become a transformative water reducing representative in the concrete market, using remarkable efficiency over standard lignosulfonates and sulfonated melamine formaldehyde (SMF)-based admixtures. As a third-generation superplasticizer, PCE enables dramatic reductions in water-to-cement ratios while preserving excellent workability, causing more powerful, more long lasting, and lasting concrete frameworks. Its molecular adaptability, low dose requirements, and compatibility with various cementitious products have made it essential in high-performance construction applications ranging from framework to architectural style.

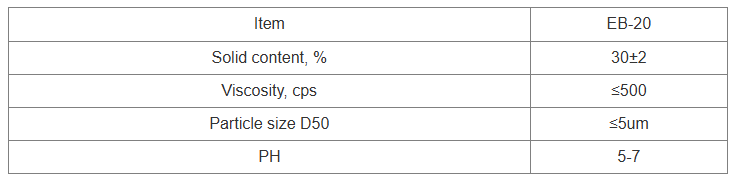

(TRUNNANO PCE Powder)

Molecular Layout and Functional Device of PCE Powder

The efficiency of PCE powder stems from its special comb-like polymer framework, including a primary chain with grafted side chains that give steric hindrance and electrostatic repulsion in between cement fragments. This dual device avoids flocculation, improves diffusion, and boosts flowability without increasing water material. Unlike earlier generations of plasticizers, PCE formulas can be precisely customized at the molecular degree to manage adsorption kinetics, slump retention, and hydration actions. This tunability allows for tailored efficiency in different environmental and application conditions, making PCE one of one of the most flexible and reliable water decreasing representatives available today.

Advantages Over Conventional Water Reducers

PCE powder supplies numerous distinct benefits over initial- and second-generation water reducers. It achieves significantly higher water decrease rates– typically going beyond 30%– making it possible for the manufacturing of ultra-high-performance concrete (UHPC) with compressive toughness above 150 MPa. Additionally, PCE exhibits minimal depression loss with time, enabling expanded workability periods throughout transport and positioning. It additionally demonstrates superb compatibility with supplemental cementitious materials (SCMs) such as fly ash, slag, and silica fume, which are critical for decreasing the carbon impact of contemporary concrete. Moreover, PCE-based admixtures are typically without chloride and sulfate contaminants, boosting lasting resilience and structural honesty.

Industrial Applications Driving Market Development

The demand for PCE powder is surging throughout multiple sectors due to its ability to meet stringent efficiency and sustainability criteria. In precast concrete manufacturing, PCE enables quicker mold release, enhanced surface area finish, and decreased energy consumption throughout healing. In framework projects like bridges, tunnels, and aquatic structures, PCE-enhanced concretes supply boosted resistance to aggressive atmospheres and mechanical stress. Green structure efforts additionally gain from PCE’s duty in making it possible for low-carbon concrete blends by making the most of SCM use. With urbanization and climate durability coming to be worldwide top priorities, PCE powder is increasingly deemed a cornerstone technology for future-ready building techniques.

Production Approaches and Technical Innovations

PCE powder is manufactured by means of regulated extreme polymerization methods such as MPEG-initiated graft copolymerization, where methacrylic acid (MAA) or acrylic acid (AA) monomers are polymerized with polyethylene glycol (PEG) side chains. Current innovations in polymer chemistry have led to the growth of multi-functional PCE versions that incorporate retardation, air entrainment, and viscosity-modifying homes right into a solitary admixture system. Spray-drying technologies have even more boosted the security and handling of PCE powders, promoting their use in dry-mix applications and automated batching systems. These developments continue to enhance both the effectiveness and flexibility of PCE in contemporary concrete modern technology.

Environmental Effect and Sustainability Considerations

As ecological guidelines tighten up around the world, the sustainability account of PCE powder is coming under increased examination. While PCE itself does not consist of dangerous VOCs or heavy steels, its production involves petrochemical feedstocks and energy-intensive procedures. Researchers are proactively discovering bio-based monomers and eco-friendly basic materials to create greener PCE alternatives. In addition, life process analyses (LCAs) are being utilized to review the general carbon impact of PCE-containing concrete systems. Efforts to boost recyclability, reduce waste during manufacturing, and integrate round economy concepts are forming the next phase of PCE growth, aligning it much more very closely with worldwide sustainability goals.

Challenges and Future Development Pathways

( TRUNNANO PCE Powder)

Despite its lots of benefits, PCE powder faces a number of challenges including expense competition, sensitivity to cement chemistry, and variability in area efficiency. Concerns such as overdosing effects, delayed setting, and conflict with specific mineral admixtures can complicate its usage in complex mix designs. To attend to these problems, recurring research focuses on establishing adaptive PCE formulations that react dynamically to adjustments in concrete structure and ambient conditions. Smart admixture systems including sensors and real-time feedback mechanisms are also being checked out to optimize efficiency in large building setups. These growths will certainly be essential to opening the complete potential of PCE in next-generation concrete innovations.

Final Thought: PCE Powder as a Driver for the Future of Concrete

Polycarboxylate ether (PCE) powder stands for a major jump ahead in concrete admixture modern technology, incorporating high efficiency with environmental responsibility. As building and construction needs advance toward higher toughness, toughness, and sustainability, PCE remains to allow cutting-edge solutions across a wide variety of applications. Through proceeded advancements in formula scientific research, production efficiency, and integration with wise construction systems, PCE powder is poised to continue to be at the forefront of the concrete revolution– forming the constructed setting of tomorrow with smarter, cleaner, and much more resilient products.

Distributor

TRUNNANO is a supplier of Concrete PCE Powder with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about , please feel free to contact us and send an inquiry.

Tags: concrete water ,reducer pce powder, polycarboxylate

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us