Discover the detailed overview to oil immersed transformers, consisting of oil immersed power transformers and oil immersed circulation transformers. Discover their functioning concepts, kinds, advantages, and progressing duty in wise grids and renewable energy.

1. Intro to Oil Immersed Transformers

In the detailed internet of our modern electrical grid, transformers play an essential function, calmly stepping voltage up and down to make sure power can be transmitted successfully over fars away and distributed safely to our homes and markets. Amongst the different kinds available, the oil immersed transformer stands as a testimony to tried and tested reliability and resilience. For decades, these workhorses have actually formed the foundation of power systems worldwide.

An oil submersed transformer is a kind of electrical transformer that utilizes a specialized shielding oil as both a coolant and a shielding medium. This layout is mainly used for tool to high-power applications, making it a foundation of electrical infrastructure. This guide delves deep right into the world of oil immersed power transformers and oil immersed distribution transformers, discovering their modern technology, applications, and their evolving function in an era of digitalization and renewable resource.

1.1 What is an Oil Immersed Transformer?

At its core, an oil submersed transformer includes a magnetic core and copper or light weight aluminum windings housed inside a secured storage tank filled with insulating oil. The key feature of the oil is twofold:

1. Insulation: The oil possesses high dielectric toughness, successfully insulating the high-voltage windings from the transformer’s core and based container. This protects against short circuits and electrical malfunctions.

2. Air conditioning: As the transformer runs, the windings generate substantial heat as a result of I ² R losses. The flowing oil absorbs this warmth, convects it to the transformer’s container walls, and dissipates it right into the bordering air. Bigger units usually include radiators or fins to raise the area for a lot more efficient cooling.

This dual-purpose use of oil makes the oil immersed transformer remarkably efficient and durable, efficient in handling high lots and standing up to transient overloads better than numerous dry-type options.

1.2 Oil Immersed Power Transformer vs. Oil Immersed Circulation Transformer

While all these systems are oil immersed transformers, they offer distinct functions within the power system network. Recognizing the difference is essential.

An oil submersed power transformer is a heavyweight, commonly utilized in transmission networks at creating stations and major substations. Their main duty is to “step-up” the voltage generated at the nuclear power plant to extremely high degrees (e.g., 138 kV, 230 kV, 500 kV and over) for effective long-distance transmission, and to “step-down” the voltage at receiving substations for additional distribution. They are defined by their very high power ratings (frequently exceeding 100 MVA), intricate building and construction, and on-load faucet changers for voltage law.

An oil immersed distribution transformer, on the various other hand, carries out the final step in the power distribution chain. It takes the medium voltage from the transmission lines (e.g., 11 kV, 33 kV) and steps it down to the reduced voltages (e.g., 400/230 V) utilized by industrial and residential consumers. You frequently discover them on energy posts (pole-mounted) or on ground-level pads (pad-mounted). They are smaller, have lower power scores (normally up to 2,500 kVA), and are made for optimal effectiveness at reduced, more constant lots.

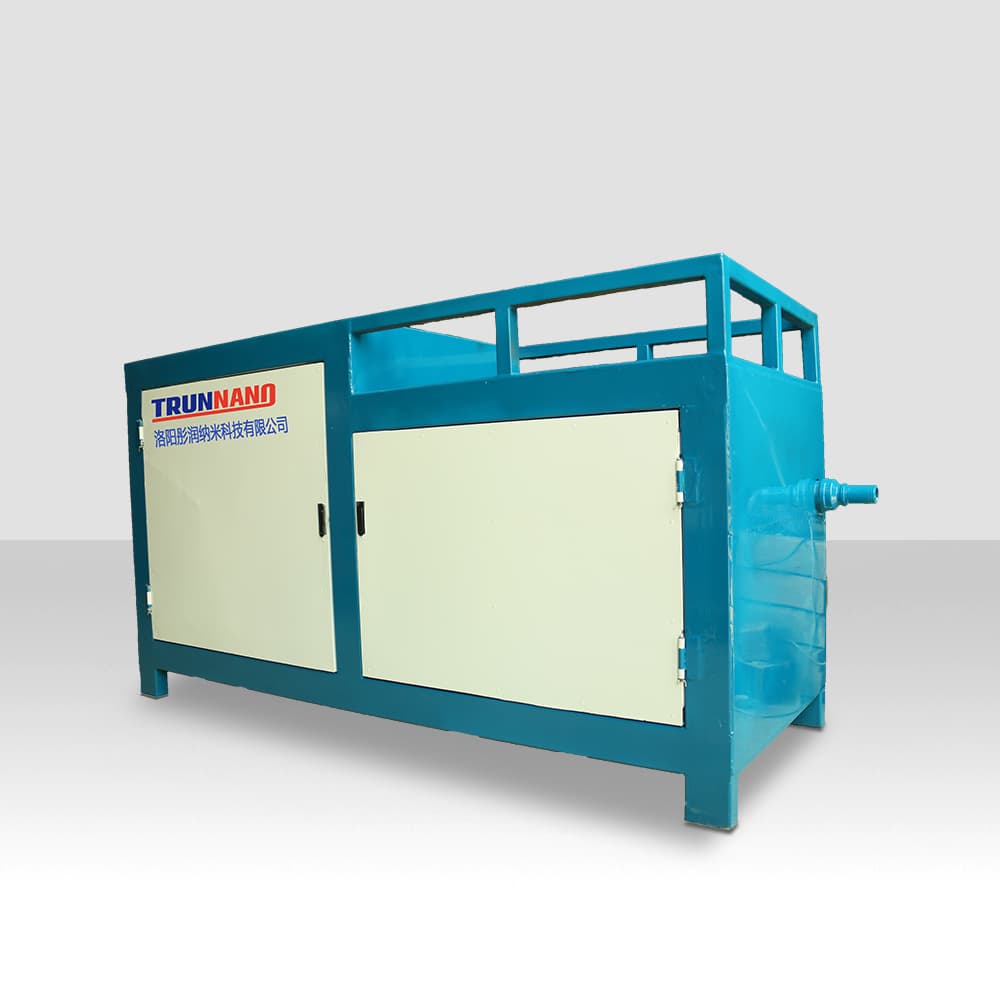

(Oil immersed power transformer)

2. Key Advantages of Oil Immersed Transformers

The long-lasting appeal of the oil immersed transformer is not unintended. It supplies a collection of compelling benefits that make it the preferred option for lots of demanding applications.

2.1 Superior Air Conditioning and Overload Capability

The remarkable thermal capacity of oil contrasted to air allows an oil immersed power transformer to handle and dissipate warm a lot more successfully. This converts to a greater overload capability. During durations of height electrical energy need, an oil immersed transformer can deal with momentary overloads without sustaining damage, an important feature for keeping grid stability. The oil’s circulation makes certain also warm circulation, preventing local hot spots that can deteriorate insulation in time.

2.2 Enhanced Insulation and Long Life Span

The combination of high-quality mineral oil and meticulously fertilized paper insulation creates a dielectric system of phenomenal strength. This durable insulation system shields the transformer from voltage rises and transients, contributing to a functional life expectancy that can reach 30-40 years or even more with proper upkeep. The secured container additionally protects the internal elements from moisture, dust, and various other atmospheric impurities.

2.3 High Efficiency and Cost-Effectiveness

For high-power applications, the oil submersed transformer is commonly the most cost-effective selection. The materials made use of– mineral oil, steel container, and copper/aluminum windings– offer a favorable balance of efficiency and cost. The high effectiveness of these transformers, especially at their rated load, leads to reduced energy losses over their life time, leading to considerable cost savings for energy firms and huge industrial users.

3. Warm Topics and Future Trends

The world of oil immersed transformers is not static. It is continuously developing to satisfy brand-new difficulties and integrate with modern technologies.

3.1 Eco-friendly and Fire-Resistant Oils

Environmental and safety and security problems are driving a substantial change away from conventional mineral oil. The marketplace is quickly taking on oil submersed transformers loaded with naturally degradable esters (synthetic or all-natural). These oils use a higher fire point (making them K-class fire-resistant), are much less toxic, and are conveniently naturally degradable, substantially lowering the ecological effect in case of a leakage. This pattern is making oil submersed circulation transformers safer for setup in metropolitan locations and environmentally sensitive places.

3.2 Combination with Smart Grids and IoT

The modern-day oil involved power transformer is ending up being an intelligent node in the clever grid. Sensing units are being integrated to keep an eye on vital specifications in real-time, including:

Dissolved Gas Evaluation (DGA): Finding fault gases created within the oil to predict incipient mistakes.

Temperature Surveillance: Tracking top-oil and hotspot temperatures.

Lots and Power Quality Surveillance.

This information, transferred by means of IoT (Internet of Points) systems, enables anticipating maintenance, prevents unexpected blackouts, and optimizes transformer utilization and lifespan.

3.3 Sustaining the Renewable Resource Transition

The international promote renewables is developing brand-new need for oil submersed transformers. Large solar farms and wind power installations call for robust oil submersed power transformers to tip up the generated voltage to transmission levels. Moreover, the intermittent nature of renewables places greater stress and anxiety on grid elements, and the proven integrity and overload capacity of oil submersed transformers make them optimal for this essential duty.

4. Choice and Maintenance Finest Practices

Picking the appropriate transformer and keeping it properly is vital to a reputable power system.

4.1 Just how to Select the Right Oil Immersed Transformer

Picking in between an oil immersed power transformer and an oil submersed distribution transformer relies on the application. Secret considerations consist of:

1. Voltage Degree and kVA Rating: Match the transformer’s requirements to your system’s requirements.

2. Application: Transmission substation, plant, or industrial distribution.

3. Location: Indoor vs. outdoor, environmental problems, and fire safety and security guidelines (which may influence the choice of insulating oil).

4. Performance Criteria: Follow regional efficiency criteria like DOE (United States) or EU CoC (Europe).

5. Spending plan: Consider both the first capital cost and the overall price of possession, consisting of losses.

(Oil immersed distribution transformer)

4.2 Vital Upkeep for Durability

Proactive upkeep is important for any kind of oil submersed transformer. A thorough program ought to include:

1. Regular Oil Tasting and Testing: Regular DGA and testing of dielectric stamina and wetness material are the most effective ways to analyze the health of the transformer.

2. Bushing and Insulation Examination: Visual look for fractures, contamination, or leakages.

3. Faucet Changer Upkeep: Routine evaluation and maintenance of on-load or off-load faucet changers.

4. Maintain it Tidy and Dry: Making sure the storage tank exterior, radiators, and rests are tidy and functional.

The oil immersed transformer, in its duties as both a high-capacity oil immersed power transformer and a common oil immersed distribution transformer, continues to be an irreplaceable element of our global power framework. Its tested layout, combined with ongoing developments in insulating fluids and electronic monitoring, guarantees it will remain to be a dependable, effective, and intelligent service for powering our globe for years ahead. As we construct the grids of the future, integrating even more renewables and digital knowledge, the durable and adaptable oil submersed transformer will most certainly go to the heart of it.

About us

Luoyang Datang Energy Technology Co., Ltd. is a high-tech enterprise integrating R&D, manufacturing and supply of power equipment such as transformers, new energy components, distribution cabinets and inverters. With technological innovation as the core, we focus on creating high-reliability and high-performance power solutions to serve global customers. With a strict quality control system and international standard certification, we continue to output excellent products and enable customers to build safe and stable power systems. If you are interested in high voltage vs medium voltage, please feel free to contact us!

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us